20 +

Years of Our Experience

- About Us

Our Commitment to Your Business Success

Roghini Minerva Engineers is a tooling trade house conceived in the year 2004 for the very purpose of providing complete tooling solutions at competitive costs. We always place maximum emphasis on the quality of the products. We offer the best products procured from the market leaders of our field.

Innovative Solutions

Our team continuously explores new technologies

Dedicated Support

We are available to assist you with challenges you face

michelle yeoh

Founder CEO

- Products

Our Products

Video Production

Media

Video Production

Media

Video Production

Media

Website Redesign

Design

Event Marketing

Event

Event Marketing

Event

User Experience

Strategy

User Experience

Strategy

Walter

Total Tooling Solutions

REGO-FIX

Tool Holding Systems

Finetech

Boring Solutions

Sharp Toolings

Indexable Special Tools

- Services

Our Services

Tooling Solutions

Powering Manufacturing with Smarter Tooling

In today’s competitive manufacturing environment, every second on the shop floor matters. Our Tooling Solutions are designed specifically for Indian manufacturers who want to increase output, improve quality, and reduce production costs—without compromising reliability.

We combine high-performance cutting tools, strong application engineering, and hands-on technical support to deliver measurable improvements in machining productivity.

Clamping Solutions

Precision. Stability. Productivity.

Our Clamping Solutions are designed to securely hold workpieces during machining, inspection, and assembly operations. By ensuring maximum stability and accuracy, our solutions help reduce setup time, improve productivity, and deliver consistent quality across every operation.

Whether for CNC machining, milling, turning, grinding, or special applications, we provide reliable clamping systems tailored to your needs.

Process Optimization

CNC Machining Tooling Excellence

Reduce cycle time. Improve tool life. Achieve consistent quality.

Our Process Optimisation service for CNC machining focuses on maximizing productivity while minimizing tooling cost, downtime, and variability. We analyze your complete machining process—from tool selection to cutting parameters—to deliver measurable improvements on the shop floor.

Project Prove outs

Proven CNC Machining Solutions. Ready for Production.

Project Prove Outs is a focused CNC machining validation service designed to eliminate risk before full-scale production. We test and optimize tooling, cutting parameters, and machining strategies under real operating conditions—ensuring predictable performance from the first production run.

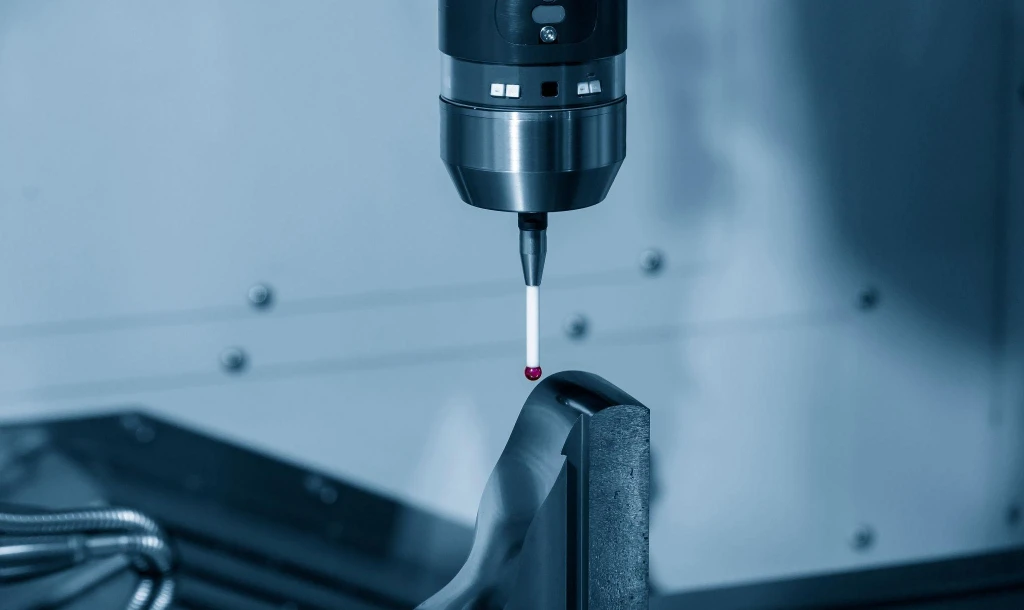

Meterology

Precision Measurement Solutions for Zero-Defect Manufacturing

In CNC machining, precision is everything. Our Metrology Equipment solutions ensure that every component you manufacture meets exact dimensional and quality standards—consistently and reliably.

We offer a complete range of high-accuracy measurement and inspection tools designed specifically for CNC machine shops, tool rooms, and precision manufacturers.

Material Handling Solutions

Smarter Movement. Higher Productivity. Better Precision.

Efficient material handling is critical to achieving consistent quality, shorter cycle times, and higher machine utilization in CNC machining. Our Material Handling Solutions are designed to seamlessly integrate with your CNC machines, tooling systems, and shop-floor workflows—ensuring smooth, safe, and automated movement of components from loading to finished output.